Vacuum Resin Impregnation

Ultra Seal gives your business the quality and service you’re looking to achieve with your investment. For clients who outsource impregnation requirements, we offer a large variety of services, which gives your business the quality and control you need for your project.

Low Volumes

If you have low volumes or just need to outsource your component impregnation, we provide a high-quality, flexible and dependable impregnation service using our unrivaled Ultra Seal System & Sealant.

High Volumes

If you have higher volumes and want to outsource, or just don’t want to invest in impregnation process equipment, we offer a hands-on solution that can handle your needs. Ultra Seal offers a cost-effective, environmentally friendly, superior impregnation solution without you having to invest in equipment or personnel.

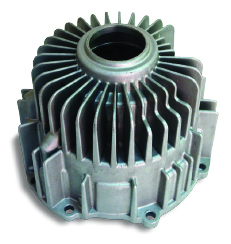

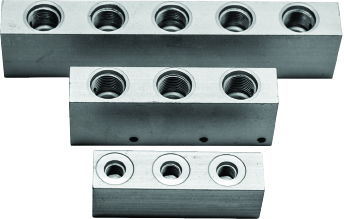

Vacuum resin impregnation is a multi-step process designed to fill the naturally occurring porosity in cast metal and powder metal components to minimize or eliminate leak paths within the casting.

- Seals Porosity in Cast Metals (Aluminum, Iron, Brass, Powdered Metals)

- Utilizes our 1955/R True Zero Discharge Resin – 100% Recoverable

- Environmentally friendly

- Certified to MIL-I-17563C

- Listed on the Navy Qualified Product List – QPL-17563

- Flexibility and dependability for both Low Volume and High Volume customers.

- Ultra Seal’s 1955/R systems and sealant are revolutionizing the impregnation industry.

- GMW3155 compliant Test, 1500 hrs. 150 C dry

- GMW3155 compliant test, 1500 hrs. 150C ATF Fluid

- Thermal Stability

- 3-5 business day turnarounds. Expedite available.

Meets the following Mil-Spec chemical resistance and thermal aging requirements:

| MATERIAL | TIME | TEMPERATURE |

| Water | 14 days | Boiling |

| Oil | 14 days | 210ºF |

| Hydrocarbon fluid | 14 days | Ambient |

| Carbon removal | 30 minutes | Ambient |

| Lubricating oil | 48 hours | 255ºF |

| Turbine fuel | 48 hours | Ambient |

| Ethylene glycol | 14 days | 300ºF |

| Hydraulic fluid | 14 days | 210ºF |

| Aviation fuel | 48 hours | Ambient |

| Diester grease | 48 hours | Ambient |

| 18% sulfuric acid | 2 hours | Ambient |

| Stoddard solvent | 48 hours | Ambient |

| Ethyl alcohol | 48 hours | Ambient |

| Thermal resistance | 14 days | 300ºF |

Exceeds Mil-Spec requirements for the following:

| MATERIAL | TIME | TEMPERATURE |

| Thermal shock | 20+ cycles | -125ºF to 425ºF |

| Dexron VI ATF | 3000 hours | 300ºF |

Typical properties (uncured):

| Chemical type | methacrylate blend |

| Appearance | amber fluorescent liquid |

| Viscosity (Zahn Cup) | 24-26 seconds |

| Specific gravity | 0.90 – 0.95 |

| Flash point | 200ºF |

| Vapor pressure | 1mm Hg |

Test conditions: 25% porosity powder aluminum test ring impregnated @ 10 torr wet vacuum for 5 minutes. Pressure tested @ 50 psi air/under water.